Culture

Inside Patagonia’s Repair Facility

Consumer Friendly Environmentalism

Inside Patagonia’s massive Reno facility, beyond conveyor belts and bins and forklifts and other apparatus moving up to 80,000 products-per-day, there’s an upstairs workshop. It’s got natural light. Lively chatter comes from 40-plus folks. Their work spaces are decorated with plants, pictures, strings of holiday lights.

This is Patagonia’s repair center. We’re a group of outdoor journalists visiting for the morning before departing to Lost Trail Lodge, a backcountry hut behind Sugar Bowl, for a few days. It’s the end of February. Sunny skies and recent snowfall means we’re gonna get it good. But first, we’re going to see Patagonia’s latest environmental campaign in action.

The facility itself is heated via hot water circulation and solar power, and the repair center is the backbone of Patagonia’s Worn Wear program. “We’re trying to make repairability cool,” says Patagonia’s Sr Global Category Marketing Manager: Technical Outdoor, Jimmy Hopper.

While much of the clothing industry sells in quarterly cycles that emphasize periodic replacement of garments, Patagonia, with snow as the centerpiece, are marketing longevity. They’ve chosen snowsports as their vehicle for this messaging because it’s the “most demanding and technical” of their divisions, according to Hopper. “Extending a garment’s life by nine months has the greatest effect on reducing environmental impact,” Hopper continues. “The greatest (environmental) impact is in the use phase.”

Sewing machines hum in front of a wall stocked with hundreds of thread colors. A couple aisles of outerwear, puffies and more that are beyond saving date back decades as a resource for repairs. What they can’t re-use, they recycle, as evidenced by giant bales on the ground floor. They’ll also purchase your used gear as part of a resale program if you want to update your kit before a product has bit the dust.

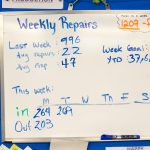

Seventy-five folks work in the repair department—48 doing hands-on repairs, 27 support staff. They complete around five repairs per day on average. Over a year, that adds up to tens of thousands of garments. They do it free under the Ironclad Guarantee, or for a reasonable price if the damage due to normal wear and tear. They also provide guidelines to customers on how to do simple repairs at home. “Some companies sweep (repair) under the rug,” says Eric Wallis, Patagonia’s Product Line Manager for Snow and Mountain Bike.

It’s environmental action through industry and redefines the relationship consumers have with brands.

Sr Product Designer Glen Morden is there with us, too, along with Designer Maggie Hill. They visit Reno regularly with a cadre of designers from Corporate Headquarters in Ventura. “Every repair informs design,” Morden explains. “It’s a circular design process.”

By better understanding where a high-end jacket, for instance, tends to break down over time, they can create solutions to improve the durability of the next rendition of said jacket, again extending its life cycle.

Glen rides a lot, and no doubt he’s happy to be here for a few days of touring. So, we head towards the backcountry. We’re all given a new outerwear kit to test through the season. I get a PowSlayer jacket/pants combo, which are made from recycled Gore-Tex, a recent innovation. Along with it are a few patches to handle minor wear and tear, should something go wrong with an edge or charlift or snow machine while out in the field.

For the next few days, we ride powder on a mix of gentle and rolling slopes, putting in long days on the skintrack. I’ll run the kit for the rest of the year, and even send the pants in for repair when I blow a zipper in the spring—it’ll take around two weeks to get them back, good as new. In fact, I’m still running those pants, and expect them to last another full year of heavy backcountry and lift-accessed boarding, maybe more, before I have to send them in again.

It may seem counter-intuitive to encourage folks to repair something before buying new. After all, aren’t increased sales the end-goal of every business? But, Patagonia has been committed to environmentalism for decades and they continue develop myriad ways to address environmental concerns regardless of the bottom line. They also understand that as fun-seekers, we are going to engage in activities that can affect the natural world. And for consumers like you and I, repair is a simple act that can reduce our own environmental impact.